Searching for an HDD drilling company?

St. Vincent Drilling is the right choice for high-quality horizontal directional drilling services at competitive prices in Lincolnshire, Nottinghamshire , Leicestershire , Derbyshire, Yorkshire, Cambridgeshire and across the UK.

Horizontal directional drilling (HDD)

HDD is a proven method of installation for all types of pipework, such as telecommunications, gas lines, clean and dirty water. HDD causes little disturbance or impact on the surrounding areas.

This is an installation method for all types of pipework enabling the crossing of obstacles in an environmentally friendly way, enabling a reduction in carbon.

A safer and more effective operation

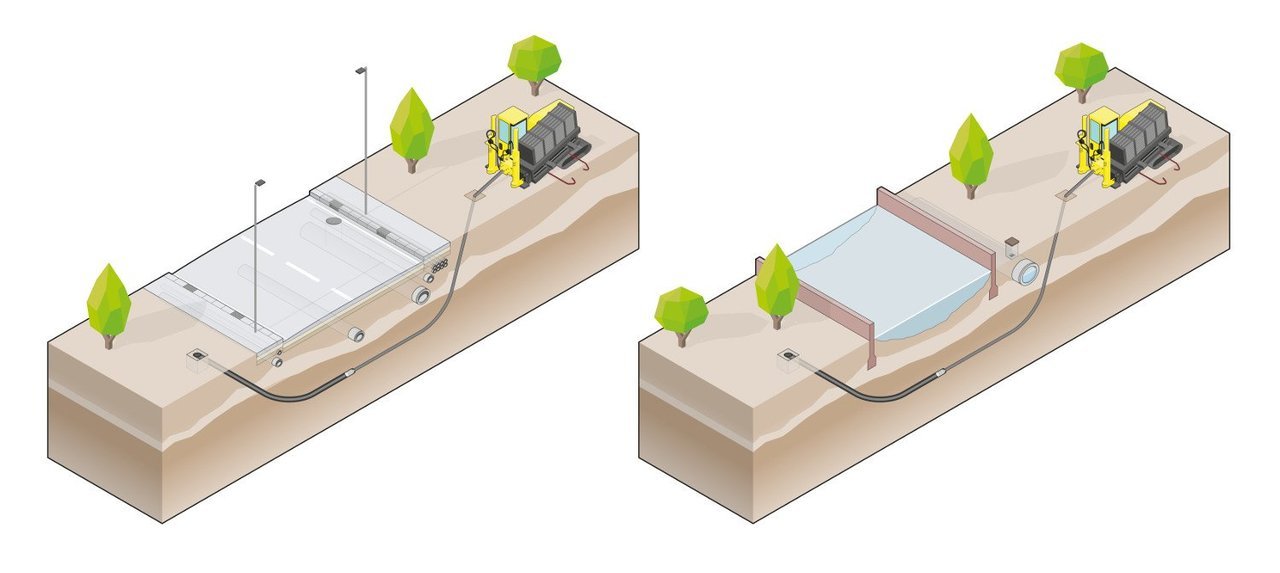

The process starts with a launch and reception pit. This pit collects the drilling fluid, which is usually removed by a vacuum tanker truck. The pilot bore is drilled along a pre-determined path set out by the site engineer. Once the pilot bore has reached the reception pit, a reamer is fitted to the drill stem. This reamer is pulled back along the pilot bore path, expanding the bore (known as back reaming). There may be more than one pass. By sizing up the reamers incrementally, the bore is expanded to 25-50% larger than the product pipe.

Finally, a towing head is attached to the product pipe, which in turn fits by a shackle arrangement to the back of the reamer allowing the drill rig to pull the pipe back along the bore path to arrive at the launch pit.

The drill requires drilling fluid, which is run through the Vermeer 850 mixer unit. The main constituent is water, which can be mixed with bentonite (clay based) or polymer depending on ground conditions. This fluid is continuously pumped to the cutting head allowing it to keep cool. It also stabilises the bore path and acts as a lubricant allowing easy passage of the product pipe. This mud can be recycled back through the rig.